Polymers

Today, polymers have become an integral part of everyday life. From grocery bags, fruits and water bottles to textile fibers, phones, computers, food packaging and toys – almost every product used in our daily routines contains polymers.

HDPE is used in various packaging applications including the manufacture of industrial containers, crates, milk jugs, detergent bottles, fruit juice caps for food packaging, jerry cans, drums, etc. HDPE provides reasonable impact strength to the end product.

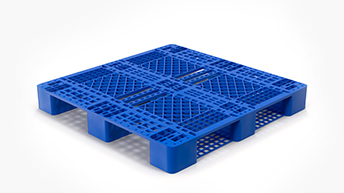

OPaLene HDPE is the most favored material for houseware making it perfect for any number of products that may spend a lot of time indoors or outdoors e.g. outdoor patio furniture; playground equipment, storage containers, trash, and recycling bins, etc.

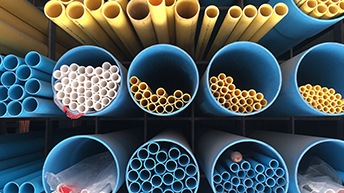

With high resistance to corrosion, exceptional weather tolerance, lightweight and flexible qualities, OPaLene HDPE is perfect for use in high-pressure pipelines, drainage pipes, agriculture, sanitation & irrigation to many other key piping usages as a means of transporting and distributing potable water at a longer distance.

Waterproof is one of the most significant features that make OPaLene HDPE a favorite choice of fertilizer manufacturers. Woven Bags made from OPaLene HDPE are flexible, durable, and tear-resistant, making the material ideal for heavy-duty packaging. Also called monofilaments, it is widely used for applications like mosquito nets, fishing nets, and also ropes and twines.

OPaLene LLDPE is used in most important applications in agriculture such as plastic mulch films and silage wrap because it is cheap, easily processed, highly durable, and flexible. Another key application is for drip irrigation pipes helps immensely in water conservation.

OPaLene LLDPE plays an important role for any multi-layer packaging films/flexible laminates used for FMCG products such as biscuits, chips, milk pouches, edible oil pouches, PET foods, spices, Coffee & Tea, Shampoos & Detergents, etc.

One of the key applications of OPaLene LLDPE is the manufacturing of rotational molded products used in a wide range of indoor/outdoor applications like water tanks, road barriers, traffic cones, industrial storage tanks for chemicals, Golf carts, components of effluent and drainage systems.

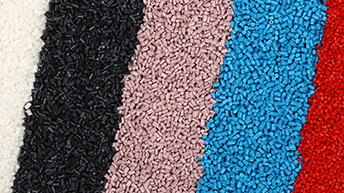

OPaLene LLDPE high-flow grades are used as a carrier resin for the production of a wide range of color and additive masterbatches (concentrates) as well as specialty compounds. Higher flow and narrow to broad molecular weight distribution properties of LLDPE material help in the high levels of pigment, additive, and filler loading due to excellent dispersion behavior.

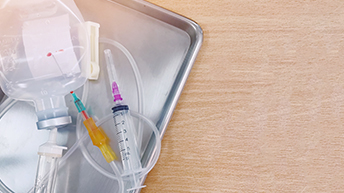

From non-woven fabrics used to protect healthcare workers from any infections such as Face masks, caps, and coveralls, sanitary diapers used to maintain the health & hygiene of children, women, and old age people to disposable injection syringes, medicine packaging, transparent IV fluid bags and so on.

Owing to its superior puncture resistance, low sealing threshold and competitive price, PP is one of the popular materials used in film extrusion. The film market applications can be divided into three main sectors:

- Food & confectioneries

- Clothing

- Tobacco products

OPaLene PP is suitable for packaging commodities like Cement, Food grain, Sugar, etc. FIBC bags made from OPaLene PP are widely used for bulk packaging applications like pharma, intermediates, hazardous chemicals, etc. PP geotextiles and geogrid are extensively used in road and bridge constructions.

Due to its low density, furniture made of OPaLene PP is extremely light which makes it easy to transport. Additionally, this furniture is distinguished by its strength and rigidity, which guarantees a long-lasting product that is difficult to break.

High-performance plastics used in cars are helping shape the future of transportation providing safety and security we need while improving fuel efficiency by reducing weight. OPaLene PP is frequently found in car bumpers, fuel tank, and even the carpet fibers of a car's flooring.